Inorganic Chemical Manufacture Acetylene Gas Calcium Carbide for Welding

Description

Basic Info

| Model NO. | Cac2 |

| Un No | 1402 |

| Certificate | SGS, ISO |

| Gas Yield | 295-305L/Kg |

| Application | Acetylene Gas |

| Purity | 99% |

| Drum Color | Customizable |

| Transport Package | in 50kg or 100kg Iron Drums |

| Specification | 0-7mm 7-15mm 15-25mm 25-50mm 50-80mm 80-120mm |

| Trademark | TYWH |

| Origin | China |

| HS Code | 28491000 |

| Production Capacity | 6000 Ton Per Month |

Product Description

Calcium Carbide

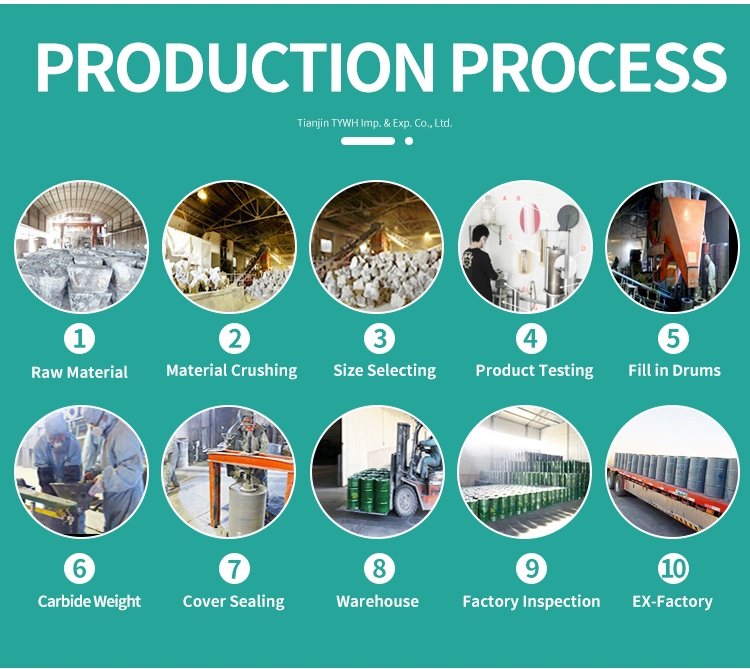

Calcium carbide is an inorganic compound,chemiacal formula is CaC2,industrial products are gray black blocks, cross-section purple or gray. It reacts violently with water, forming acetylene and releasing heat. This is an important chemical raw material, mainly used to produce acetylene gas. Also used in organic synthesis, oxyacetylene welding,fruit ripening and so on. Product Process

Spcification

| ITEM | INDEX | |||||

| Gas Yield20°C 101.3 KpaL/kg ≥ | Size | Gas Yield | Size percentage | Ash,% | ||

| Top | A Grade | Accept Grade | ||||

| 80-120mm | 300 | 295 | 280 | ≥90 | ≤1 | |

| 50-80mm | 300 | 295 | 280 | ≥90 | ≤1 | |

| 25-50mm | 300 | 295 | 280 | ≥90 | ≤1 | |

| 15-25mm | 300 | 285 | 260 | ≥90 | ≤1 | |

| 7-15mm | 290 | 270 | 250 | ≥90 | ≤1 | |

| 4-7mm | 280 | 260 | 240 | ≥90 | ≤1 | |

| 2-4mm | 260 | 240 | 220 | ≥90 | ≤1 | |

| PH3 %(V/V) ≤ | 0.08 | |||||

| H2S %(V/V) ≤ | 0.1 | |||||

| Quality Standard | GB10665-2004 | |||||

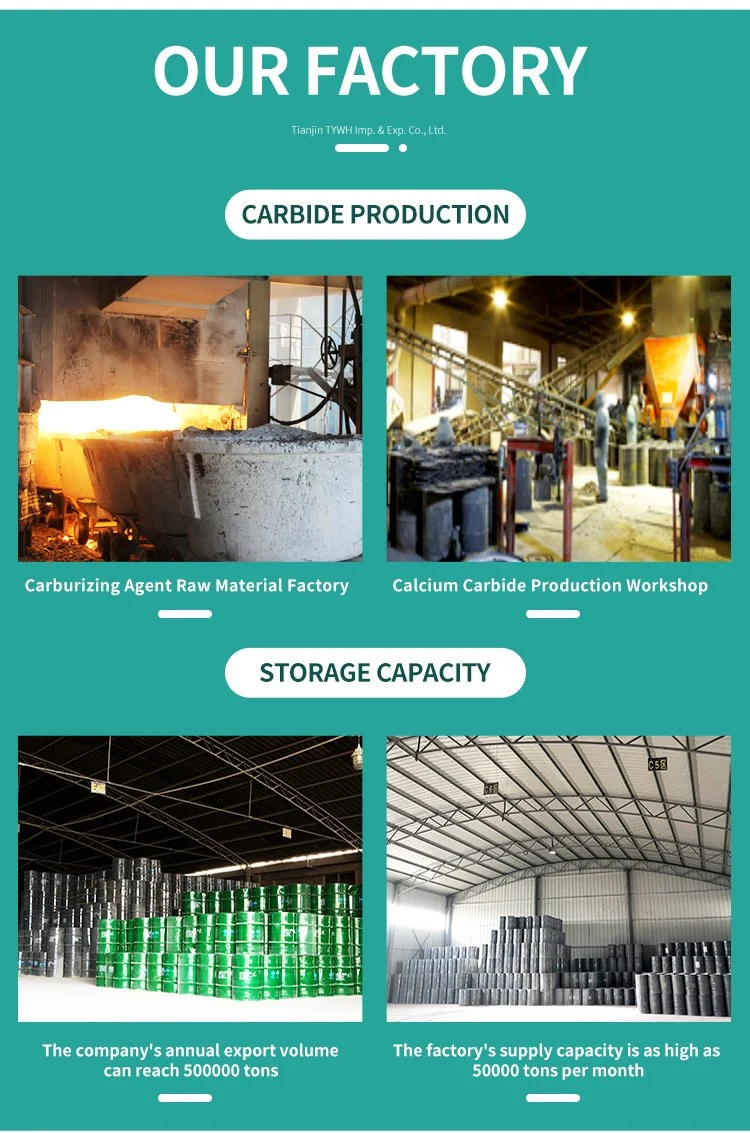

Q: Where is your plant located? Could we visit your plant?

A:Our carbide process & crush plant is located in Inner Mongolia, which is near carbide raw material place. We welcome all the valuable & precious customers visit us from all over the world.

Q: How can you guarantee the quality?

A: We will take a lot of sampling testing second time during carbide processing to ensure products with good gas yield.

We often do air pressure testing to drums, ensure carbide drums seals tight and safety.

Different sizes stored separately to avoid size mixing.

We will take sampling test again before goods loading, ensures loaded goods with correct weight, sizes, gas yield and quantity.

Our carbide Production is based on Chinese National Standard: GB10665-2004.

Q: What is the gas yield?

A: Typically, the gas yield of the particle size 80-120mm, 50-80mm, 25-50mm is 295L/KG.

The relationship between the gas yield and calcium carbide is as following. | ||||||||

CaC2 (%) | 63.14 | 68.52 | 72.54 | 73.89 | 75.2 | 76.57 | 77.91 | 80.6 |

Gas Yield(L/Kg) | 235 | 255 | 270 | 275 | 280 | 285 | 290 | 300 |

Q: What is the delivery time?

A: It is usually within 20 days after receiving the deposit or original L/C.

Prev: Inorganic Chemicals Product Calcium Carbide Cac2

Next: Hongding Chemical Titanium Dioxide Trutile in Inorganic Pigment /TiO2 PVC

Our Contact